More Durable Concrete With a Nano-Engineered Sealer

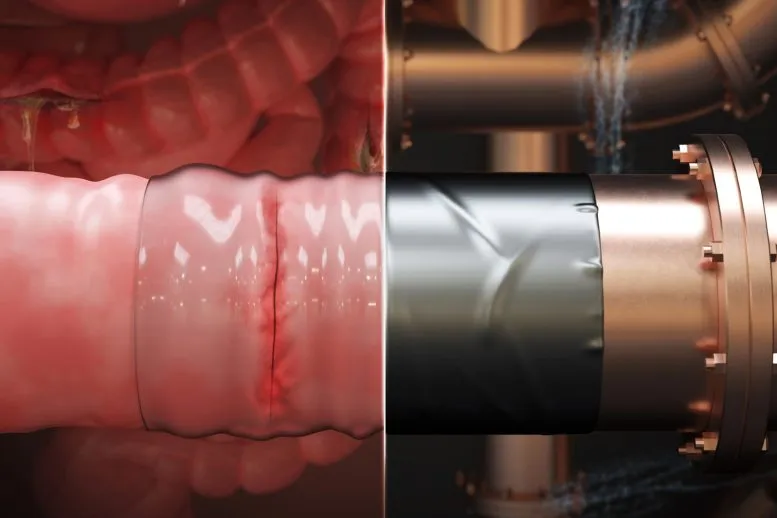

A nanomaterials-engineered penetrating sealer developed by Washington State University researchers is able to better protect concrete from moisture and salt – the two most damaging factors in crumbling concrete infrastructure in northern states.

The novel sealer showed a 75% improvement in repelling water and a 44% improvement in reducing salt damage in laboratory studies compared to a commercial sealer. The work could provide an additional way to address the challenge of aging bridges and pavements in the U.S.

“We focused on one of the main culprits that compromises the integrity and durability of concrete, which is moisture,” said Xianming Shi, professor in the Department of Civil and Environmental Engineering who led the work. “If you can keep concrete dry, the vast majority of durability problems would go away.”

Shi and graduate student Zhipeng Li recently published their work in the Journal of Materials in Civil Engineering and have applied for a provisional patent.

Much of the nation’s critical infrastructure, such as the U.S. highway system, was built from the 1950s to the 1970s and is now reaching the end of the lifetime for which it was designed. Every four years since the late 1990s, the American Society of Civil Engineers has provided a report card of U.S. infrastructure that shows consistently poor or failing grades. About 8% of approximately 600,000 bridges in the U.S. are considered structurally deficient, and one out of every five miles of highway pavement is in poor condition. The problem is exacerbated in cold climates by multiple freeze and thaw cycles and by the increased use of deicer salts in recent decades, which can degrade the concrete.

“Concrete, even though it seems like solid rock, is basically a sponge when you look at it under a microscope,” Shi said. “It’s a highly porous, non-homogenous composite material.”

Topical sealers have emerged as one tool to protect concrete, and many state departments of transportation use them to protect bridge decks in particular, which seem to suffer the worst from salt damage. The sealers on the market provide some level of protection, but moisture is often able to make its way into the concrete, Shi said.

In their study, the researchers added two nanomaterials, graphene oxide and montmorillonite nanoclay, to a commercial siliconate-based sealer. The nanomaterials densified the microstructure of the concrete, making it more difficult for liquid water to penetrate. They also formed a barrier against the intrusion of water vapor and other gasses that tend to make their way into the concrete. The nanomaterial also protected the concrete from the physical and chemical attacks of deicing salts. The penetrating sealer is designed to be multi-functional, as it can also serve as a curing aid for fresh concrete.

The WSU sealer is water-based instead of using any organic solvent, which means it’s more environmentally friendly and safer for workers, Shi added

“Traditionally, when you switch from an organic solvent to water, you sacrifice the sealer’s performance,” he said. “We demonstrated that the use of nanomaterials mitigates that reduction in performance.”

The researchers have done preliminary market analysis with industry stakeholders and are studying ways to further optimize the sealers. They are investigating how the nanomaterials-based sealers might help protect concrete from microbial damage or abrasion, the daily wear and tear that damages the material in high-traffic areas. They plan to conduct pilot-scale demonstrations in the next two years, deploying an experiment of concrete infrastructure on the WSU campus or in the city of Pullman.

Reference: “Effects of Nanomaterials on Engineering Performance of a Potassium Methyl Siliconate–Based Sealer for Cementitious Composite” by Zhipeng Li, S.M.ASCE and Xianming Shi, F.ASCE, 16 February 2022, Journal of Materials in Civil Engineering. DOI: 10.1061/MT.1943-5533.0004148